Tamellin Services

Welcome to the world of Tamellin, where carpentry becomes an art and innovation meets precision. We offer a wide range of services, from pre-production consulting to advanced industrial production, with value-added services such as painting and pre-assembly. Our philosophy is based on creating direct partnerships with customers, actively involving us in production to ensure superior quality results. With Tamellin, your vision takes shape in an all-encompassing way, guided by our experience and commitment to excellence. We are ready to shape the future together with you.

Consulting

We support you right from the design phase. We have a technical staff specialised in the use of 3D software, always available to find the right solution for your needs.

Warehouse

Fully automatic management of the loading and unloading of material to and from the various plants. We have 254 drawers for storing plates to be processed and for moving semi-finished products to the next cycles.

Cut

Uncoiling of galvanised, aluminised and iron coils up to 2.5 mm thick and 1500 mm wide, by in-line straightening with shear.

Laser cutting

Thanks to our 6kw fibre laser, we cut various materials with precision. The working range 1500×4000 and automatic loading/unloading allow the cutting of pickled sheet metal, stainless steel, aluminium and copper.

Punching

We use a punching machine with an angle shear to process stainless steel, copper and aluminium on a 1500×4000 mm field, connected to the automatic warehouse to handle machining operations and material handling.

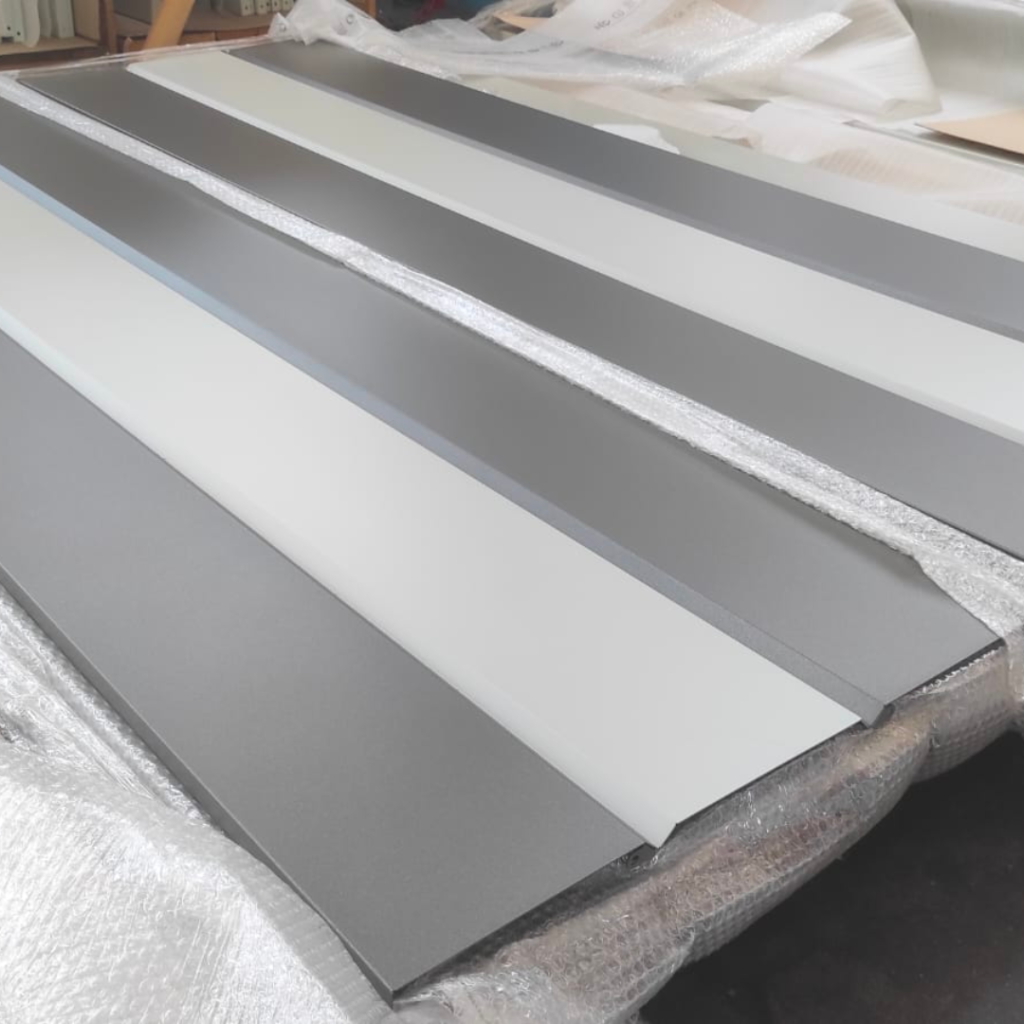

EB Panelling

Our panelising machine optimises folding, ideal for mass production and customised panels of various sizes.

It processes iron, aluminium, and stainless steel up to 2 mm, performing unique special bends even on already punched sheets.

RAS panelling

With an additional machine of the latest generation, we simultaneously perform special radiusing and bending operations up to a length of 4000 mm with high levels of precision

Bending

CNC bender presses with various powers and lengths, operated by experienced personnel who take care of maintenance and updating of numerical controls.

Calendering

Our new 2-roller machine offers superior circular accuracy, handles large batches quickly and is ideal for circular channels with diameters from 150 mm to 1000 mm.

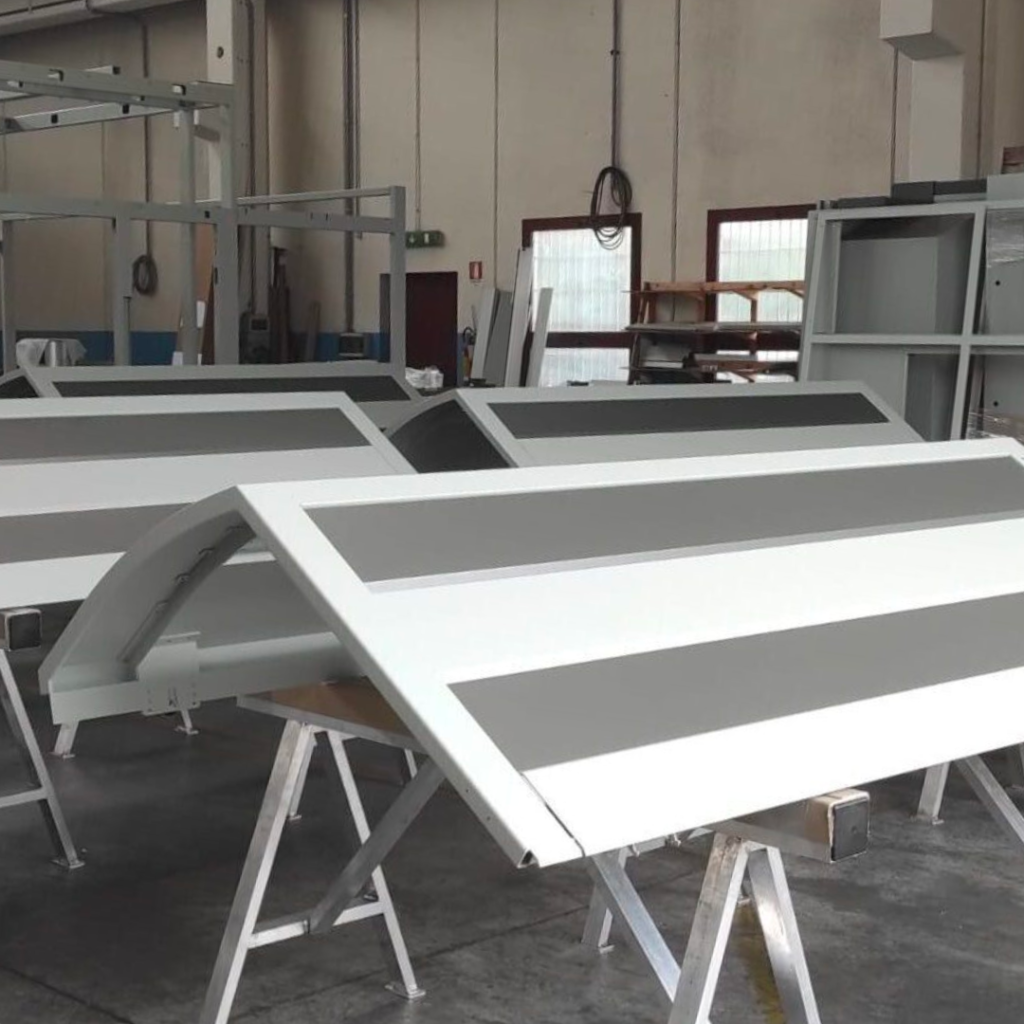

Assembly

We carry out MIG and TIG welding on semi-finished products, assembly by tacking and application of threaded inserts or rivets, as well as polishing and finishing of parts for subsequent treatment.

Testing And Assembly

The assembly department prepares shipments according to customer lists, while the testing department works closely with production. The staff is constantly trained in the use of measuring instruments and procedures, ensuring strict control of all stages. Specific checks are possible on request.

Treatments

With the help of our well-established network of qualified suppliers, we are able to offer a management service for surface treatments such as painting, galvanising, burnishing and phosphating.

Transport

With our order management software, we plan shipments with precision. Finished products are sorted by order and optimally packaged before being delivered by qualified transporters.